FHWA DEMONSTRATION

FINDS TREASURE UNDER THE INTERSTATE

Interstate 40 (I-40)

is a major east-west transcontinental highway running

through the southeastern and southwestern portions

of the United States from North Carolina to California.

Much of the pavement surfacing on I-40 within the

states of Arizona and New Mexico is so badly potholed

as to create a safety hazard for drivers. In response,

the New Mexico Department of Transportation (NMDOT)

recently closed down the eastbound lanes of I-40

near Gallup for three consecutive nights, entirely

shutting down for repairs all eastbound lanes of

the Interstate to all automobile and truck traffic,

a dramatic course of action in this day and age.

NMDOT spokesperson Delane Baros announced the following

day that this same section of highway would likely

have to be shut down again as the new repairs started

to fail almost immediately, and then adding, “The

reason being is because the bulk of the soil underneath

is clay, and then the subgrade is just completely

saturated with moisture.”

Following wet winter

weather conditions, some potholing and pavement

failure on I-40 is not abnormal, but the severity

of the problem this year is particularly troubling.

The Governor of Arizona recently held a press conference

to inform residents that millions of dollars will

be made available for repair work on Interstate

40 and the State of New Mexico issued a press release

announcing that they are conducting a study for

the reconstruction of I-40 all the way from Albuquerque

to the Arizona state line, a project of approximately

150 miles. The current estimated cost for that highway

improvement project in New Mexico is $830 million.

With Average Annual Daily Traffic (AADT) of 20,000

cars and trucks, 30% of which is truck traffic,

that works out to approximately four trucks and

ten cars per minute impacting the I-40 pavements

on an around-the-clock basis. At that traffic volume,

with both cars and trucks swerving in and out of

their lanes to avoid potholes and distressed areas,

these pavement failures are creating serious hazards

for road users and nightmares for the road maintenance

crews. Earlier this year, the local county sheriff

blamed potholes on I-40 as the cause of multiple

crashes and remarked that the pothole problem is

only getting worse. As history has proven, these

repairs will only function as temporary Band-Aids

until a more permanent and sustainable solution

is implemented to preserve the life of these pavements

for decades of safe, maintenance-free service, and

not just a few years.

| “The

reason being is because the bulk of the soil

underneath is clay, and then the subgrade is

just completely saturated with moisture.” |

TIMELY DISCOVERY

OF A SOLUTION

Timely then is the

recent discovery of the outstanding performance

of one segment of an I-40 reconstruction project

that incorporated innovative stabilization product

technology in two miles of its construction. As

recently confirmed by Mr. Eugene Hosteen, NMDOT’s

current Area Maintenance Supervisor in charge of

the maintenance of the I-40 pavements in this area

of the state, two miles of eastbound I-40 pavement

remain smooth-running and free of repairs after

23 years in service with “nothing more than

a fog seal applied” to the pavement surface

in recent years. While other I-40 pavements in this

area of New Mexico are currently potholed and have

been subject to complete reconstruction and numerous

repairs throughout the same period of years, the

trouble-free performance of this one section of

I-40 stands out as exceptional. Even more so, this

two mile segment of eastbound I-40 was historically

NMDOT’s worst area in the entire 150 mile

length of I-40 between Albuquerque and the Arizona

border. Last reconstructed in Year 2000, this two

mile section of I-40 featured use of advanced liquid

stabilization products with the encouragement of

the Federal Highway Administration (FHWA) New Mexico

Division Office. The project was designated as a

FHWA Demonstration Project, and involved the full-depth

reconstruction (complete removal and disposal of

asphalt pavement, aggregate base materials and saturated

soils below pavement elevation) of four miles of

I-40, identified as Milepost 93 to Milepost 97,

and included the two miles featuring the stabilization

of both the subgrade soils and aggregate base course

materials.

WORST I-40

PAVEMENT BETWEEN ALBUQUERQUE AND AZ STATE LINE

This four mile section

of Interstate reconstruction just happened to include

the two mile section of eastbound lanes that Will

Williamson, NMDOT’s Area Maintenance Supervisor

at that time, identified in his experience as “THE”

worst maintenance problem between Albuquerque and

the Arizona state line. The eastbound lanes of Interstate

40 that he was speaking about were located between

Milepost 94 and Milepost 96 (MP 94 – MP 96),

within the limits of the I-40 MP 93 – MP 97

reconstruction project. This section of I-40 transects

the Acoma Indian Reservation and runs through a

mountainous valley, much of which is underlain by

the El Malpais lava fields. One of the lava flows

runs parallel to the south side of I-40. This lava

flow interrupts the natural downslope drainage under

the highway and acts as a dam that traps water within

the silty clay and organic soils deposits located

immediately beneath the eastbound lanes. This unique

geology creates a worst case condition of trapped

groundwater directly underneath a pavement supporting

heavy truck traffic. Many other sections of I-40

are plagued with high groundwater, but the two miles

between MP 94 - MP 96 were considered by NMDOT Maintenance

as their very worst pavement problem. The worst

case.

PREDICTIONS

BASED ON CONVENTIONAL PAVEMENT DESIGNS

The MP 94 –

MP 96 section of eastbound I-40 had previously required

full depth reconstruction every 2 to 3 years, while

the westbound lanes constructed on more solid ground

were far less problematic. During reconstruction

of the eastbound lanes in Year 2000, NMDOT District

6 Engineer Larry Maynard commented that he anticipated

another full depth reconstruction project of this

same section would be required in less than three

years. Ron Clark, the Superintendent for contractor

WW Construction (WWC), predicted failure and reconstruction

within two years. He mentioned in a testimonial

letter that it was very difficult to work on top

of the native soils under the eastbound lanes that

were composed of “soft wet silt, clay and

dark stinking organic soils.” NMDOT and WWC

had worked together reconstructing many other sections

of I-40 between Albuquerque and the Arizona state

line during this same period of years, so both men

were speaking from extensive experience when making

these predictions.

Prior to year 2000,

when the I-40 MP 93 – MP 97 project was completed,

and during subsequent years, NMDOT was relying on

conventional pavement designs during reconstruction

of other sections of I-40, and basically increasing

the thickness of the asphalt pavement and the aggregate

base course layers as a continuing response to the

ongoing pavement failures. Their primary method

of dealing with localized subgrade failures during

these reconstruction projects was deep excavation

of saturated soils and replacement with virgin and

recycled aggregate materials reinforced with a combination

of geogrids and geotextile fabric products. Nothing

was done during these projects to treat the moisture

sensitive clay subgrades under the pavement structural

section. Consequently, none of these pavement reconstruction

projects have matched the extended performance of

the Eastbound MP 94 – MP 96 pavement installation

that incorporated base course materials and subgrade

soils treated with the EMC SQUARED System liquid

stabilizer products as part of the FHWA Demonstration

Project. The pavements constructed on top of these

EMC SQUARED stabilized subgrade and base course

layers were constructed over worst case ground conditions,

with an asphalt pavement section that was reduced

in thickness by two (2) inches, yet they remain

free of potholes and repairs twenty-three (23) years

later. The eastbound MP 94 – MP 96 pavements

will soon exceed the service life predicted by the

District Engineer and by the Construction Superintendent

by a factor of eight (8) times, with no sign of

failure currently anticipated.

INNOVATIVE

TECHNOLOGY SOLVES AN UNSOLVABLE PROBLEM

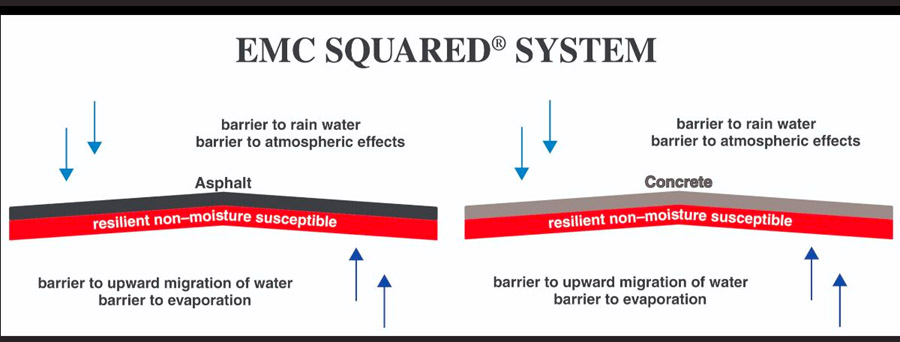

Potholes in highway

pavements are widely understood to be the result

of base and subgrade failures under the pavement,

failures generated by the presence of water in the

base materials and subgrade soils. Until measures

are taken to keep water out of the base and subgrade

layers, potholes and pavement failures will continue

to be a costly and dangerous problem. Ever thickening

layers of moisture and frost susceptible base course

materials will not eliminate the problem. Thicker

layers of asphalt pavement will not eliminate the

problem of water in the base course layer. Suction

and capillary attraction will continue to draw moisture

and pull ground water upwards into moisture susceptible

base materials, particularly when placed on top

of moisture susceptible subgrade soils. Geogrids

and geotextile fabrics may add tensile strength

and reduce the upward flow of clay particles via

capillary water into the base layer, but they do

nothing to keep the base material and the subgrade

soils dry and able to retain the strength that was

assumed in the pavement design. The addition of

cement and lime chemicals to base or subgrade layers

can increase the strength of the layer, but there

is no historical evidence that they eliminate the

moisture susceptibility problem itself, the problem

that continues to draw water in and saturate base

course and subgrade layers. For example, the I-40

MP 93 – 97 lanes reconstructed in year 2000

were previously constructed with asphalt pavement

placed on top of cement treated base (CTB) and that

pavement didn’t last three years. The EMC

SQUARED treatments instead keep the moisture content

in the base course layer and subgrade in a stable

state, without major fluctuations, while also functioning

as a moisture barrier impeding the upward and downward

movement of water within the pavement structural

section. The moisture barrier aspect of the EMC

SQUARED System stabilizer treatments is the clue

to understanding why the I-40 eastbound MP 94 –

MP 96 pavements, constructed on the EMC SQUARED

Subgrade and EMC SQUARED Base Course layers, can

remain smooth running and free of repairs 23 years

later, even with ground water trapped in the native

soils immediately below the stabilized subgrade

and base course layers.

COHESIVE FORCES

BRIDGE UNDERLYING SOFT SOIL DEPOSITS

The exceptional

performance of freeway and highway pavements constructed

on foundation materials stabilized with EMC SQUARED

System liquid stabilizer products is not unique

to New Mexico. The solution to solving the frequent

failures of the I-40 pavements in New Mexico involved

utilization of the EMC SQUARED stabilizer products

to keep water out of the treated layers. After 23

years of trouble-free service, the long term benefits

of the EMC SQUARED stabilizer treatments for extending

pavement service life are now obvious, but also

noteworthy is the advantage the contactor achieved

by applying the EMC SQUARED treatments during construction,

giving themselves the ability to continue construction

uninterrupted by the delays that they would have

otherwise experienced while digging out and repairing

soft spots in their subgrade and backfilling with

layers of aggregate and geosynthetic reinforcement.

These unique stabilizer products also produce a

reaction in soils that rapidly generate increased

internal cohesive forces that help the stabilized

layer quickly bridge saturated soils below the subgrade.

Such bridging performance is unique to the EMC SQUARED

System stabilizer products.

MONITORING

OF FHWA DEMONSTRATION PROJECT

Ray Pederson, the

FHWA Area Engineer who was on site throughout the

construction of the eastbound lanes, was aware of

the particularly complicated geology underneath

this section of Interstate when he made the decision

to monitor on an ongoing basis the entire MP 93

– MP 97 project. Ray was a Professional Engineer

(P.E.) with a Materials Engineering background.

His intention was to evaluate whether the use of

the EMC SQUARED System liquid stabilizer products,

or the other chemical and mechanical stabilization

products used during this challenging highway construction

project, significantly contributed to extending

pavement service life. The variation in the underlying

ground conditions and the number of different methods

of stabilization made this a complicated monitoring

task, but Pederson was determined to make something

of value out of this Demonstration Project. To his

great credit, it was his 13-year monitoring effort

that finally led to the uncovering of a treasure

trove of information that otherwise would have remained

buried without his perseverance. The clues that

led him to his findings were being accumulated annually

by state crews operating high-speed profilers to

measure the smoothness, or the rate the pavement

was developing roughness in the form of International

Roughness Index (IRI) measurements. IRI measurements

are the international standard for evaluating highway

pavement performance. They provide the basis for

predicting the amount of service life remaining

in a particular segment of highway pavement.

UNCOVERING

THE CLUES TO FIND THE TREASURE

As FHWA Area Engineer

Pederson reported in his September 8, 2013, letter,

where he compared the performance of various different

chemical and mechanical stabilization measures used

during the construction of the MP 93 – MP

97 project, which is included as page 13 of summary

(https://stabilizationproducts.net/docs/18809.pdf),

nothing more than routine maintenance operations

were conducted during his 13 years of monitoring.

A thin bituminous treatment (Novachip) was applied

to the westbound lanes in 2008 and to the eastbound

lanes in 2009, and the following year an Open Graded

Friction Course was applied to the entire project

and adjacent sections of highway as a safety measure.

Pederson was onsite

during the 1999 – 2000 construction phases

of the I-40 MP 93 – MP 97 project. He was

aware of the fact that the eastbound lanes were

constructed on top of the worst case ground conditions

in this length of Interstate 40, while the westbound

lanes were constructed on a more solid native subgrade.

During construction, one mile of the subgrade soils

under the westbound MP 93 – MP 97 lanes had

been left untreated, with no chemical stabilizer

product applied. The soft spots in this one mile

section of subgrade were over excavated and replaced

with aggregate materials reinforced by a combination

of geotextile and geogrid products, but the subgrade

soils were otherwise left untreated. The remaining

three miles of subgrade soils were treated with

lime chemical. The second phase of the MP 93 –

MP 97 project used the EMC SQUARED liquid stabilizer

products during the construction of eastbound lanes

from MP 94 to MP 96. In the case of the construction

of the eastbound lanes, two out of the four miles

of subgrade were left untreated, with localized

repairs conducted on an as needed basis, in similar

manner as the untreated subgrade on the westbound

side.

STAYING ON

TASK AND FOLLOWING THE CLUES TO THE SOLUTION

Area Engineer Pederson

was aware that the different ground conditions underlying

the westbound and eastbound pavements were fundamentally

influencing the IRI test results. He concluded that

the monitoring program must incorporate the two

different starting points for the IRI measurements

and separate monitoring of the westbound and eastbound

lanes in order to properly measure and compare their

rates of deterioration over time, and not just their

initial smoothness at the time they were constructed.

He went on to collect the IRI monitoring results

over a period of ten years. He also made comparisons

with the different methods of subgrade construction

that were used under the westbound pavements and

the under the eastbound pavements, in each case

comparing pavement smoothness above the stabilized

subgrade to the pavement smoothness above the sections

of subgrade that were not chemically treated or

reinforced with the geosynthetic products. This

analysis allowed him to demonstrate that both the

lime treatment and EMC SQUARED treatments were clearly

beneficial in helping retain pavement smoothness

and prolong pavement service life. The first take

away that he achieved in analyzing the data from

this Demonstration Project was that chemical stabilization

of the subgrade soils under I-40 in this area of

New Mexico is highly cost-effective, in this case

using either lime or the EMC SQUARED System stabilizer

products.

Pederson was also

assigned as Area Engineer to two other NMDOT construction

projects on I-40 that were in progress during this

same period of years, and he reported that the smoothness

test results for the pavements constructed above

these chemically stabilized subgrades were superior

to those of the new segments of I-40 pavement being

constructed at both ends of the MP 93 – MP

97 project without use of chemical subgrade treatments.

The IRI data also confirmed over time that the EMC

SQUARED System applications were more effective

than lime treatment in preserving pavement condition

and prolonging service life, and once again more

effective than the geosynthetic products in preserving

pavement smoothness and service life. Using the

Theoretical Design Life calculations developed by

NMDOT to interpret the IRI data, Peterson was accurate

in his prediction that the EMC SQUARED System treatments

would be by far the most effective treatment measure

for extending pavement service life. For additional

perspective, the EMC SQUARED System treatments were

also the lowest cost to purchase and fastest to

install.

LESSONS TO

BE LEARNED

Given the current

pothole epidemic that is seriously endangering the

safety of I-40 highway users in Arizona and New

Mexico, along with the revelation by NMDOT that

they recognize pothole pavement failures are caused

by saturated clay subgrades, the conclusion could

be drawn that the Department of Transportation should

expand approval and use of stabilizers products

that counteract the movement of water into highway

subgrade soils. As proven by this FHWA Demonstration

Project on Interstate 40, there is an affordable

alternative to short-lived conventional construction.

Interstate Highways can be designed with moisture-resistant

foundation materials that have the year-round solid

support that asphalt pavements require to provide

decades of pothole-resistant service.

VIDEO TOUR

OF EASTBOUND I-40 MP 94 - MP 96 ABOVE EMC SQUARED

STABILIZED SUBGRADE AND BASE COURSE

Take a one minute

video tour of the eastbound MP 94 – MP 96

segment of Interstate 40. This pavement was constructed

on top of subgrade and base course layers treated

with the EMC SQUARED System products to keep water

out of the base course materials and subgrade soils.

This section has been 23 years in service over worst

case ground conditions without need for repair or

reconstruction. The video footage was taken in April

2023, in the midst of the current epidemic of hazardous

potholes that have made other sections of Interstate

40 in both Arizona and New Mexico truly life-threatening

to drive, and that have caused repeated shutdowns

of the Interstate for pothole repairs.

FOR AN EVEN

DEEPER DIVE

For a deeper dive

into the related construction history and the monitoring

results of the 13 year study conducted by the FHWA

Area Engineer, visit https://stabilizationproducts.net/docs/18809.pdf

NOTE: If you are interested

in the studies conducted by independent soil and

pavement materials testing laboratories, whose results

give evidence as to the how and why the performance

of EMC SQUARED System stabilizer products prolonged

the service life of the FHWA Demonstration Project

on Interstate 40, look for the next newsletter coming

soon. In case you missed one, earlier newsletters

describing laboratory and field tests, as well as

projects in North America can be found here: https://stabilizationproducts.net/newsletters.html

For a summary report

on other smooth running highways built on EMC SQUARED

subgrades constructed above deep deposits of expansive

clay soils, visit

https://stabilizationproducts.net/docs/18791.pdf

and

https://stabilizationproducts.net/docs/18468.pdf