The

smoothness and ride quality of a freeway, highway,

road or city street is more important than most

people realize. Why? In addition to reducing the

maintenance costs and improving the fuel mileage

of the trucks and cars driving on the pavement,

the smooth riding or rough riding behavior of the

pavement has everything to do with the number of

years before it will require major repairs, or complete

removal and replacement. Monitoring and measurement

of the rate a pavement develops roughness is internationally

recognized as the standard method for determining

the remaining service life of a specific length

of pavement. The federal government’s Department

of Transportation (U.S. DOT), through its Federal

Highway Administration (FHWA), has mandated since

1990 that the Department of Transportation of each

state annually evaluate and report on the smoothness

of all federally financed freeways, highways and

roads within their state boundaries. The measuring

system is known as the International Roughness Index

(IRI). It provides feedback to the federal government

on the quality of each state’s design and

construction programs in building their paved road

networks. It also shows which states need to improve

their technology and construction procedures to

deliver pavements with service life measured in

decades rather than years. Cement, Fly Ash and Lime,

the conventional stabilizer chemicals, have been

in use since the 1950’s in attempts to improve

the strength of base course and subgrade layers

under highway pavements, but they are costly to

apply and of limited effectiveness in controlling

the primary enemy of pavement durability and smoothness,

which is localized or differential settlement. According

to the data that has been produced from the annual

IRI field testing conducted by each state DOT and

provided to FHWA, an advanced stabilization product

technology is proving to be far more effective in

prolonging the maintenance-free smooth-running performance

of asphalt and concrete pavements. These economical

concentrated liquid stabilizers, known as the EMC

SQUARED® System products, are simply added to

the compaction water during the standard procedures

used to construct the subgrade and base course layers

for asphalt and concrete pavements. This is a case

of doing more with less, the essence of sustainable

construction. The hyperlinks provided below report

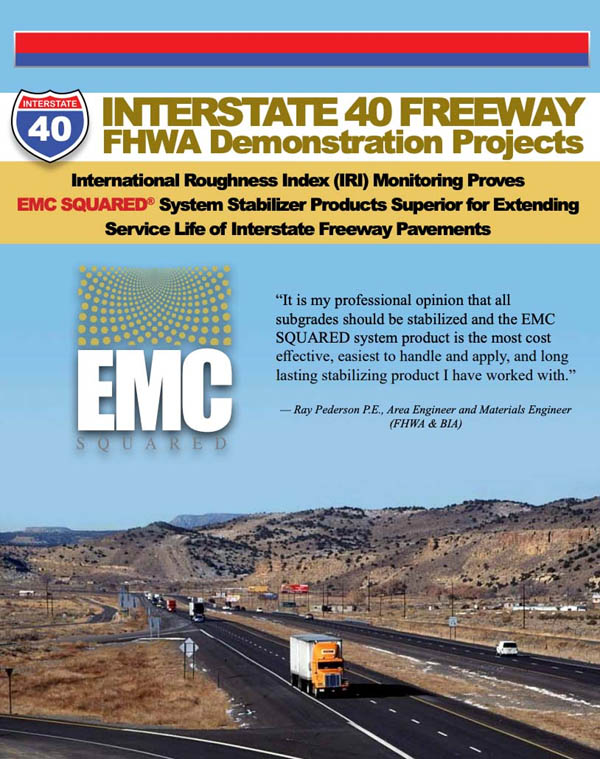

on a total of seven highway projects, including

two major tollways and four sections of interstate

highways located in two different states. Two of

these interstate highway projects using the EMC

SQUARED System stabilizer products with excellent

results were FHWA Demonstration Projects:

Click

on documents below for more information

These

two lengths of pavements were constructed over worst

case soil conditions that had previously failed

pavements constructed on a layer of cement treated

aggregate base course materials. The EMC SQUARED

System stabilization treatments of aggregate base

and subgrade soils dramatically outperformed cement,

lime, and geosynthetic products in reducing pavement

maintenance requirements and retaining pavement

smoothness. The IRI monitoring data provided by

the two state transportation departments reveals

the performance advantages of this newer generation

stabilization technology that provides superior

resiliency and all-weather support for asphalt and

concrete pavements.

For

IRI test results and case histories on 5 additional

highway projects, click here