FIELD MONITORING

AND LABORATORY STUDIES GIVE WINDOW INTO EXCEPTIONAL

PERMANENCE

ABSTRACT

Our most recent

newsletter featured a case study about a segment

of Interstate Highway pavement in New Mexico, designed

with its base course and subgrade treated with the

innovative EMC SQUARED System liquid stabilizer

products. As of 2024 the extended service life of

this pavement will be eight times beyond the lifespan

of the conventionally designed pavement that it

replaced.

https://stabilizationproducts.net/newsletters_buriedtreasure.html

The previous pavement failed and required full depth

replacement within three years of its construction,

in spite of being designed with a thick layer of

asphalt pavement placed on top of a cement treated

base (CTB) course. Also of note, highway pavements

constructed in Texas that used these same liquid

stabilizer products for treatment of subgrade soils

remain smooth running and in excellent condition

over this same extended time, remaining far smoother-running

than nearby highways built on subgrade soils that

were treated with cement, fly ash and lime, three

calcium-based chemicals. In all cases, the exceptional

performance of the pavements designed with base

courses and subgrades treated with EMC SQUARED System

stabilizer products is even more noteworthy because

these highways were constructed on top of the most

highly problematic soils and worst-case ground conditions.

Compared to the calcium-based chemical stabilizers

and the geosynthetic products that the Federal Highway

Administration (FHWA) promotes online and in the

training courses they provide regarding soil stabilization

and base reinforcement, more innovative product

technology is now delivering superior results in

prolonging the smooth-running behavior of asphalt

and concrete pavements. The monitoring and measurement

of pavement smoothness according to the International

Roughness Index (IRI) is internationally recognized

as the most important measure of highway pavement

performance. It provides a means to evaluate and

compare the performance of different reinforcement

and stabilization products in prolonging the lifespan

of pavements. While the EMC SQUARED System products

produced exceptional results in the field and in

materials testing laboratories, proponents of the

old calcium-based chemical treatments dismissed

the impressive performance of the newer generation

products on the basis that they hadn’t yet

withstood the test of time by demonstrating the

permanence of their benefits in major highway applications.

Now that the tables have turned, with highways constructed

on EMC SQUARED treated materials maintaining superior

smoothness and pavement condition for well over

two decades, the opportunity is here to review the

engineering basis behind the exceptional performance

record of these advanced stabilizer products. This

report will summarize materials testing conducted

by the State of New Mexico and the New Mexico office

of an internationally prominent geotechnical and

materials testing firm, as well as the results from

three research studies conducted by two of the most

highly regarded university-based highway engineering

organizations in the United States.

LABORATORY

TESTS PROVIDE THE ENGINEERING BASIS FOR DESIGNING

HIGHWAYS WITH BASE COURSE AND SUBGRADE STABILIZED

WITH EMC SQUARED SYSTEM STABILIZATION TREATMENTS

Presented here is

an assortment of laboratory test results from independent

third-party studies conducted by highway research

and materials engineers in the interest of helping

reviewers better understand why these newer generation

stabilizer products are so successful in the most

important of all performance categories: Prolonging

Pavement Smoothness and Extending Pavement Service

Life. In regard to the Interstate Highway success

story in New Mexico that is referenced above, constructed

as a Federal Highway Administration (FHWA) Demonstration

Project under the direction of the New Mexico Department

of Transportation (NMDOT), only limited testing

took place in the state’s materials testing

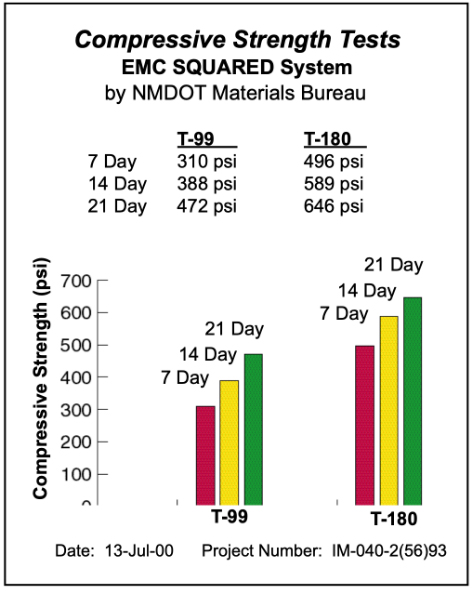

laboratories prior to or during construction. Unconfined

Compressive Strength (UCS) tests were conducted

with soil materials sampled from the Interstate

40 MP 93– MP 97 project and treated with EMC

SQUARED System liquid stabilizer products. As illustrated

in the state’s UCS test results shown below,

the subgrade soils treated with the EMC SQUARED

System stabilizer treatment easily exceeded the

200 psi minimum after 7 days curing that the state

had set as their standard for stabilized soils used

in highway subgrade construction.

NEW

MEXICO DEPARTMENT OF TRANSPORTATION UCS TEST RESULTS

In the interest

of serving reviewers with a wider range of engineering

test data regarding the performance benefits yielded

by this stabilizer treatment, the Albuquerque office

of AMEC Earth & Environmental (now Wood Group)

was contracted to conduct additional tests with

soils sampled from the Interstate 40 project. This

laboratory study included Resistance Value (R-value)

testing of both the untreated soil and soil treated

with EMC SQUARED System stabilizer products. By

testing soils treated with the stabilizers, as well

as testing the same soils without the addition of

the stabilizer treatment, reviewers are given the

ability to compare performance values both before

and after the application of the stabilizer treatment,

and ascertain the extent of improvement. UCS testing

measures shear strength, while the R-value is a

stiffness test measuring the resistance of compacted

aggregate and soil materials to deformation. AMEC

staff also sampled soils from two other NMDOT highway

locations and subjected those soils to both UCS

and R-value tests to afford reviewers with the additional

perspective on the performance of the stabilizer

products in treatment of three different soil materials.

In the case of each of the three soil materials,

the EMC SQUARED System treatment proved notably

effective, an example being the Unconfined Compressive

Strength test results from the state materials laboratory

graphed below.

This laboratory testing

series measured the increasing strength of the stabilized

material over time and evaluated the gain in strength

achieved by using the level of compaction energy

specified for application of the EMC SQUARED Stabilizer

products. https://stabilizationproducts.net/docs/18846.pdf

The performance

of the Interstate 40 pavement (Eastbound MP 94–MP

96) constructed over worst case native ground conditions

with its subgrade and base course layers stabilized

with EMC SQUARED System treatments has proven exceptional

for more than two decades. Referencing the White

Paper available via the hyperlink above, the results

of the R-value laboratory tests associated with

the EMC SQUARED Stabilized Subgrade for this segment

of interstate highway reveal in laboratory language

just how major the improvement EMC SQUARED Stabilizer

treatment made in increasing the resistance of the

stabilized soil to deformation. For reviewers not

versed in the R-value test index, an aggregate material

must test at R-value 78 or higher to meet specifications

for highway base course applications (Caltrans).

An R-value of 10 is considered the equivalent of

CBR 1, the very lowest number value on the CBR index

and representative of a soil with extremely poor

load bearing capacity. As the R-value test results

graphed in the White Paper illustrate, we can see

that the untreated soil sampled from the I-40 subgrade

was improved by the application of the EMC SQUARED

System treatment from a very low R-value of 11 up

to an R-value of 71, nearly meeting the specification

requirements to qualify as an aggregate base course

material. Another clayey soil sampled from the subgrade

of US 550, a highway project similarly located in

northwestern region of New Mexico, was improved

to an even higher R-value by the same stabilization

treatment.

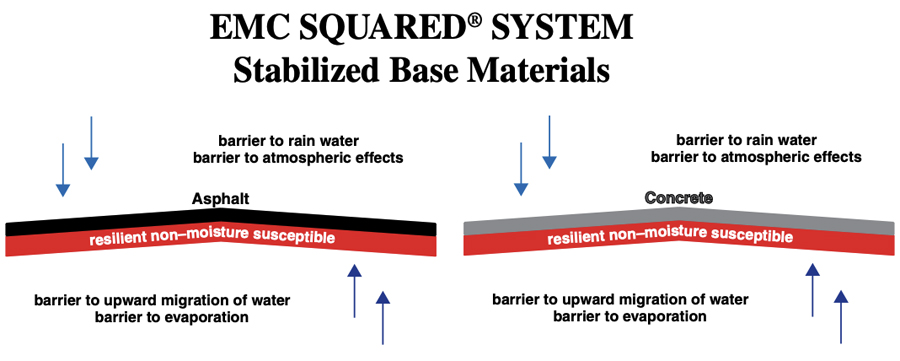

RESEARCH STUDY

#1 – MOISTURE-RESISTANT STABILIZED AGGREGATE

MATERIALS

The pavement design

of the Eastbound MP 94–MP 96 segment of the

I-40 Demonstration Project incorporated the installation

of an EMC SQUARED Stabilized Aggregate base course

layer in combination with the EMC SQUARED Stabilized

Subgrade, further increasing the stiffness of the

pavement structural section and reducing the moisture

and frost susceptibility of the critically important

foundation layers under the asphalt pavement. While

no testing was conducted by the State of New Mexico

at that time to evaluate the performance of the

EMC SQUARED Stabilized Aggregate material or the

aggregate material prior to application of the stabilizer

treatment, it is fortunate that testing was later

conducted at two nationally recognized materials

testing laboratories on EMC SQUARED Stabilized Aggregate

mixtures formulated with the same and similar aggregate

materials sampled from another project in New Mexico.

The same aggregate material treated with the EMC

SQUARED Stabilizer that was used in construction

of the base course for Eastbound MP 94–MP

96 segment of the Demonstration Project, was evaluated

in a Tube Suction Testing study conducted at the

Texas Transportation Institute (TTI) at Texas A&M

University. Tube Suction Testing uses dielectric

values and electrical conductivity, two electrical

property measurements, to determine which aggregate

base course materials are appropriate for use in

road construction and to identify those that are

prone to failure as a result of their moisture and

frost susceptibility. The aggregate base material

identified in the study as New Mexico was sourced

from the supplier that produced the crushed aggregate

base materials used in the construction of the previously

referenced Demonstration Project on Interstate 40.

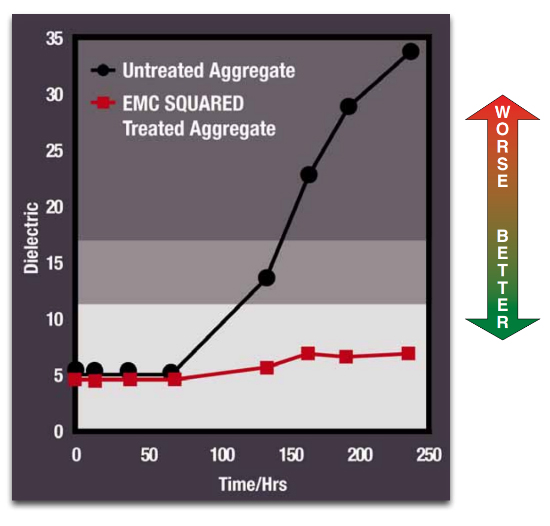

As illustrated in the graph of the Tube Suction

Test results shown below, this New Mexico aggregate

was a highly moisture and frost susceptible material

and it was used extensively, without the application

of the stabilizer treatment, for many other I-40

reconstruction projects in this same area of New

Mexico. The extremely poor performance of this aggregate

source in the Tube Suction Test conducted at TTI

is one important clue as to why this length of Interstate

40 has been so highly prone to premature pavement

failures. As is evident in reviewing the graphed

test results and the Research Report referenced

in the hyperlink below, this same problematic aggregate

material after treatment with the EMC SQUARED Stabilizer,

performed similarly to asphalt and concrete pavement

materials in resistance to damage by moisture and

frost effects.

https://stabilizationproducts.net/docs/18587.pdf

New Mexico

Aggregate Tube Suction Test Results

RESEARCH

STUDY #2 – NEW APPROACH TO STABILIZATION OF

SUBGRADE SOILS

The research study

summarized above was conducted at the Texas Transportation

Institute (TTI) using electrical property measurements

to evaluate the moisture and frost susceptibility

of aggregate materials, both before and after treatment

with the EMC SQUARED Stabilizer. A second study

conducted at TTI under the direction of Dr. Robert

Lytton, an internationally recognized authority

on the engineering behavior of expansive clay soils,

was focused on stabilization of soils rather than

aggregate materials. This second study also included

the use of electrical property measurements to determine

if a stabilized soil mixture has an acceptably low

level moisture susceptibility to be considered for

use in highway construction. Of important note,

the study was focused on stabilizing soils in a

manner not previously considered by highway engineers

schooled in the belief that the chemical soil stabilization

process is exclusively the realm of the calcium-based

stabilizers, cement, fly ash and lime. Dr. Lytton

defined the goal of the study as identifying a product

technology that would do something more than what

can be achieved with the application of bulk chemical

products, such as lime. In addition to effectively

increasing the strength and stiffness of the soil

so as to provide a stable working platform for construction

traffic, he also wanted to identify a chemical treatment

that would provide two additional benefits, the

first being “decrease the permeability of

the treated soil to reduce the amount of water penetrating

into the natural subgrade from the surface,”

and secondly to “decrease suction of the treated

soil below that of the natural soil so the treated

layer will not attract water from below.”

Dr. Lytton envisioned an entirely new approach to

defining the goal of subgrade stabilization. As

a result, we now have full scale highway demonstration

projects that have been in service for over two

decades, proving the wisdom of Dr. Lytton’s

insight into extending pavement service life by

using stabilizer products that improve the engineering

behavior of soils in radically different manner

than calcium-based chemicals. As he predicted, keeping

water out of the subgrade under pavements is the

key to extending smooth-running behavior and service

life. The FHWA Demonstration Project on I-40 featured

in the previous Newsletter is an outstanding example

of this new design concept at work.

This second research

study at TTI was conducted for the purpose of identifying

an alternative to the use of lime stabilizer products

and consequently evaluated lime treatment as well

as the EMC SQUARED System stabilizer treatment for

sake of comparison. The study found the EMC SQUARED

System stabilizers to be “Superior to lime

treatment in terms of strength, stiffness, permeability

and swell resistance” and specifically recommended

their use for an interstate highway project and

a turnpike project that were subsequently constructed

on subgrades treated with EMC SQUARED System stabilizer

products. The final report recommended the use of

EMC SQUARED System stabilizer products as alternatives

to lime treatment and made special mention of the

suitability of water tight subgrades for construction

of highway pavements running across worst case ground

conditions and deep deposits of expansive clay soils.

https://stabilizationproducts.net/docs/18588.pdf

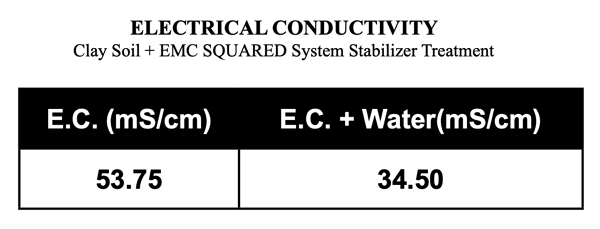

In regard to the suitability

of stabilized soils for subgrade construction, this

study set the upper limit for Electrical Conductivity

at 100 milliSiemens per centimeter. As documented

below, the soil stabilized with the EMC SQUARED

System treatment easily passed this test requirement,

and then tested even more impressively four months

after being continually subjected to moisture conditioning

treatment.

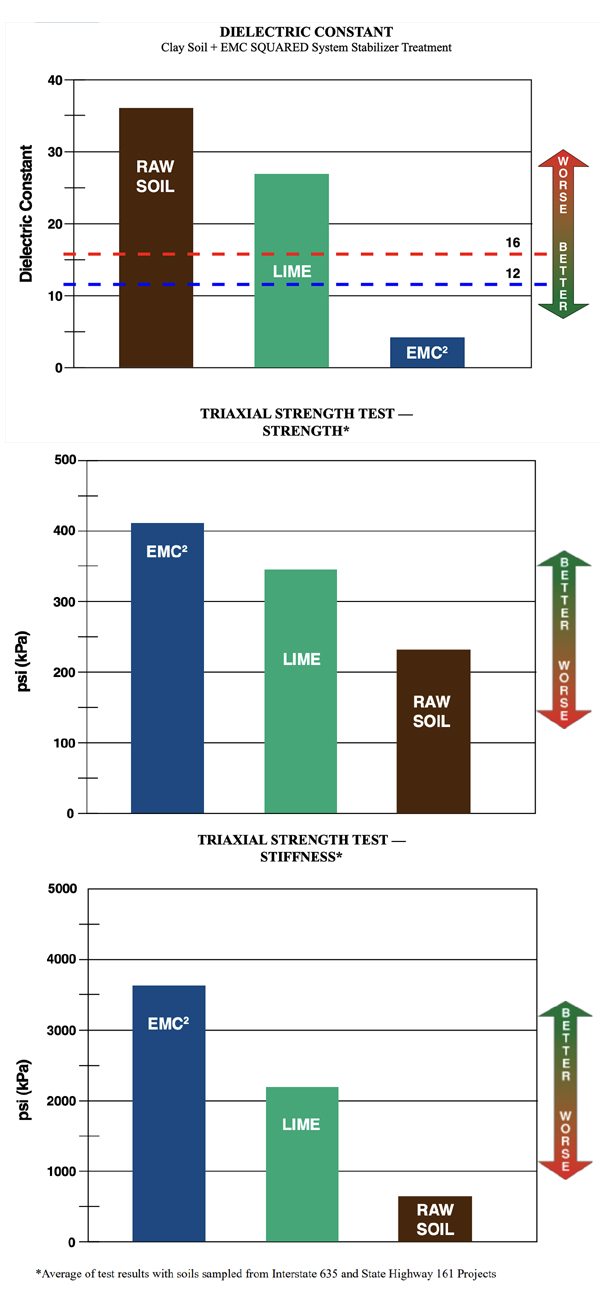

This study measured

the Dielectric Constant of an EMC SQUARED stabilized

soil material, setting the upper limit as a Dielectric

Value of 12, just below the Dielectric Value of

16, which is the point at which plastic deformation

of the pavement is predicted as the result of the

physical property changes in the soil driven by

moisture infiltration and fluctuations in moisture

content. Dielectric constants below 11 indicate

that the treated soil can adequately resist plastic

deformation and can maintain sufficient water tightness.

This study also evaluated the untreated or “raw”

soil, as well as the same soil treated with lime

chemical. As indicated below, the soil treated with

the EMC SQUARED System application was highly resistant

to moisture infiltration, while the raw soil and

the lime treated soil were both highly moisture

susceptible and unacceptable for subgrade construction.

RESEARCH

STUDY #3 – PERFORMANCE OF EMC SQUARED STABILIZED

AGGREGATE IN PAVEMENT MATERIALS TESTING LABORATORY

EVALUATION

The third research

study relevant to the performance of the EMC SQUARED

Stabilized Aggregate base course layer within the

pavement structural section of the I-40 Demonstration

Project was conducted in the asphalt pavement materials

testing laboratory at the Western Regional Superpave

Center (WRSC) at the University of Nevada Reno.

The source of the untreated aggregate material used

in the Second Research Study was located in south

central New Mexico and was similar to the aggregate

source for the I-40 projects in gradation and plasticity.

This second project involved the construction of

over 116 miles of military supply roads designed

with a base course layer constructed with locally

available soils treated with applications of EMC

SQUARED Stabilizer and a running surface constructed

with EMC SQUARED Stabilized Aggregate materials.

Given the pavement-like performance of the stabilized

aggregate running surface, state-of-the-art Dynamic

Modulus and Repeated Load Triaxial (RLT) test methods

typically used to evaluate Hot Mix Asphalt pavement

materials were used to evaluate the stabilized aggregate

mixture and compare its performance with that of

typical hot mix asphalt mixtures. Hot Mix Asphalt

(HMA) is a viscoelastic material, meaning it loses

its modulus, or stiffness, as temperatures warm

or as load weights are increased. Responsive to

the viscoelastic nature of HMA materials, the Dynamic

Modulus test method evaluates the structural response

of HMA materials under various combinations of traffic

loads, speed and environmental conditions, including

temperature variations ranging from below freezing

to 130°F. To make an “apples versus apples”

comparison between a typical viscoelastic HMA mixture

and an elastic EMC SQUARED Stabilized Aggregate

pavement, the Dynamic Modulus and RLT were the test

methods that could provide a sophisticated and meaningful

comparison between these two different kinds of

flexible materials.

Interestingly, the

EMC SQUARED Stabilized Aggregate maintained elastic

behavior and consistently good modulus value regardless

of changes in temperature and loading frequency.

The stabilized aggregate, in fact, had a higher

modulus than the asphalt pavement in testing at

all temperatures ranging from below 70°F to

130°F (21.11°C to 54.44°C). Thirty thousand

pounds per square inch (30,000 psi) is typically

assumed in design as the modulus value for aggregate

base course materials. As graphed in the technical

summary report available in the hyperlink below,

the stabilized aggregate mixture had a modulus of

over 250,000 psi within 24 hours of curing and 475,000

psi after 7 days of curing. This is approximately

the same modulus as a typical asphalt mixture exhibits

when it is tested in Dynamic Modulus at a temperature

of 55°F (12.78°C). Much like concrete pavement

mixtures, EMC SQUARED Stabilized Aggregate mixtures

go on to cure and improve over time, but they are

ready to support traffic almost immediately upon

placement.

Based upon the results

of the Repeated Load Triaxial testing that was also

conducted in the WRSC pavement testing laboratory,

the conclusion of the study was that the stabilized

aggregate material “..is not anticipated to

generate any permanent deformation under a wide

range of loading conditions.” (Dr. Peter Sebaaly)

https://stabilizationproducts.net/docs/18828.pdf

SUMMARY

The presence of

a stabilized base course layer with such exceptional

engineering test values supporting the asphalt pavement

on the Eastbound MP 94 – MP 96 segment of

Interstate 40 helps explain why this particular

segment of heavily trafficked highway pavement is

going on 24 years of trouble-free service when the

previous conventionally designed pavement that it

replaced had completely failed after just 3 years.

As evident in this summary review of material testing

studies, there is a solid engineering basis behind

this demonstration of the permanence of EMC SQUARED

System stabilizer treatments on the Interstate Highway

System.

IMPLEMENTATION

PLAN

No one chemical

or mechanical stabilization product is going to

solve every problem, or turn every soil or aggregate

material into a high-stability, moisture-resistant

layer. While field testing is recommended whenever

feasible, modern performance-based laboratory test

methods can be used to design road and highway projects

that fully realize the cost benefits of including

stabilized base courses and subgrades constructed

with EMC SQUARED System stabilizer treatments. The

economic advantages of this process, typically a

third the cost of cement or lime treatment, and

a small fraction of the cost of importing crushed

aggregate materials, are so great that investment

in state-of-the-art laboratory testing and design

services is cost justified. Paralleling the old

saying “You have to spend money to make money,”

in order to save big money on construction costs

and extend pavement service life, a fraction of

one percent of the potential savings will need to

be invested in laboratory testing preliminary to

project design phase. Contact our office for technical

assistance.